CIPO3: Custom Intelligent Production Optimization

Hello, I am CIPO —

• I create lean production in the most complex processes

• I build lean production despite very diversified products

• I reduce order processing time

• I reduce the inventory of current products and costs associated with handling

• I increase plant productivity

• I allow better controling bottlenecks

• I minimize delays

• I control the amount of stock in waiting areas as well as shipping

• I react in real time to changes in the status of the production floor

• I react in real time to human decisions

• I increase annual corporate profit from 2% to 5%

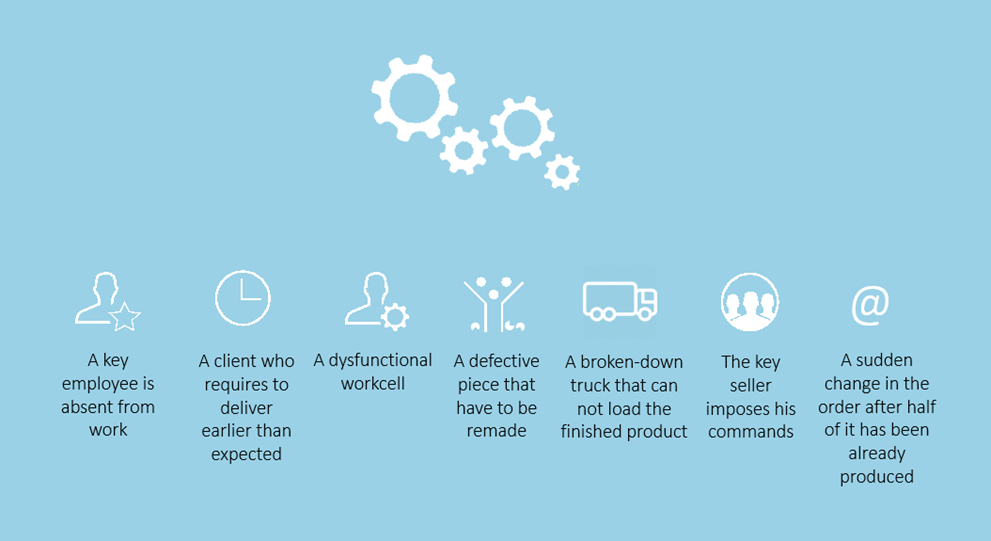

Have you ever faced these multiple challenges during production?

I attempt to overcome these events by assigning their estimated time into production. I do not plan what will happen, but rather what should be produced over a buffer (associated with the inefficiency). My approach is to recognize the inefficiency and manage it.

The principal idea (premise of the patent)

|

I attemp to predict and optimize in advance all the work to do. My algorithms deduce the parts to be processed for each employee/cell every hour of the day, and often several days in advance. Rather than predicting what each employee/cell will be doing, I try to predict what is the best piece to be treated at this particular moment by a particular employee. |

|

Real-time management

|

I reorganize the work according to an actual situation in the plant.

|

What does this mean for your business?

|

⇓ Delays ⇓ Inventory ⇓ Quality errors ⇓ Machinery ⇓ Work in process |

⇑ Productivity ⇑ Respect the space ⇑ Customer loyalty ⇑ New markets ⇑ PROFITS |

|

I am CIPO —

I am the next step